| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | ENG |

| Model Number : | 175000 |

| Certification : | API, AISI, ISO |

| Price : | USD 2000-20000 Unit |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 5000 PCS / Year |

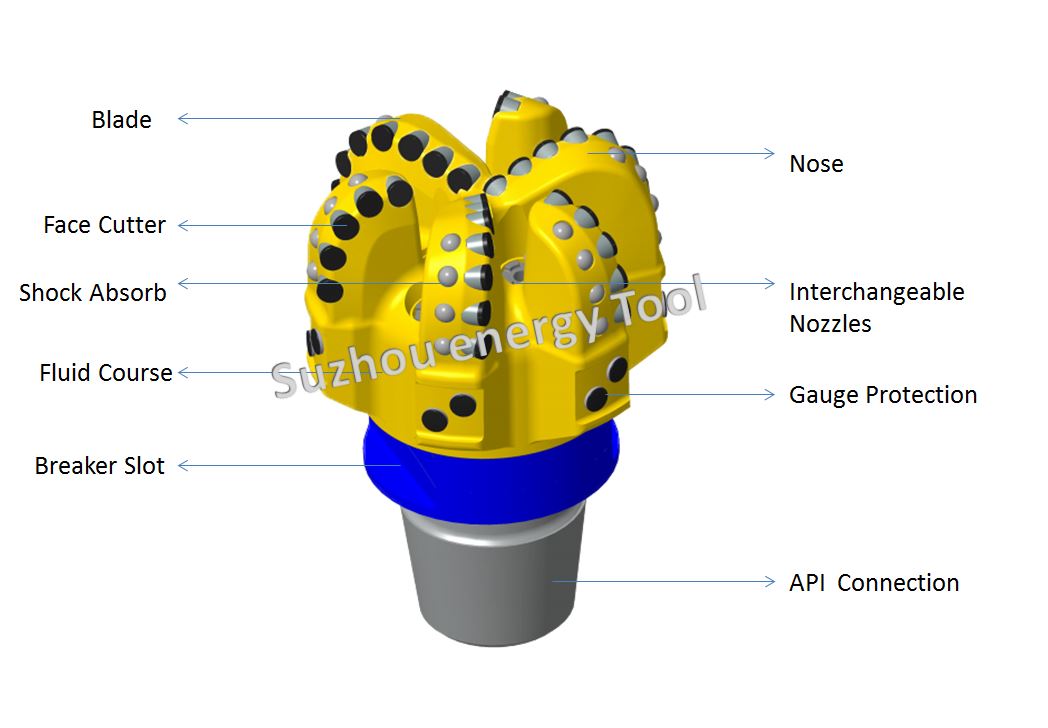

PDC Drill Bit 17-1/2 " of oil Well Hard Formation Drilling Tool

1 . Descriptions:

The Diamond PDC bit utilizes the power of "Polycrystalline Diamond Compact" (PDC) technology, transforming the effectiveness and durability of drill bits in oil drilling activities.

Exemplifying top-tier quality, the S616 PDC drilling bit functions impeccably as a fixed-head tool, providing consistent and reliable performance during drilling operations.

When choosing a PDC drill bit, critical factors such as cutter density, dimensions, bit shape, and blade style play crucial roles in determining performance across different drilling scenarios.

Our assortment of PDC bits strictly complies with API standards, ensuring seamless integration with drilling procedures. These bits are offered in sizes ranging from 3 to 22 inches with 3 to 9 blades, featuring a variety of cutter options tailored to specific requirements and budgets.

2. Specification:

PDC bits such as the S616 or M616 are specified with a 6-blade steel or matrix body and a 16mm main cutter. The IADC code indicates whether the bit is suitable for hard, soft or specific profile formations, providing additional insight.

So the IADC 323 have different mean of the PDC drill bit.

| SPECIFICATION | |

| Size : | 17-1/2 inch (44.5 m) |

| Drill Body Type : | Steel Body |

| Blades Quantity : | 7 |

| Nozzles Quantity : | 10 |

| API Connection (in) : | 6-5/8" REG |

| Gauge Length (In): | 5 |

| OPERATIONAL PARAMETERS | |

| Weight on Bit (KN): | 67-200 |

| RPM Range(Rotary): | 100- DHM |

| Flow Rate(lps): | 57-76 LPM |

| Make-Up Torque(KN): | 46-54 KN.M |

3 . PDC Drill Bit profile

There are different type of PDC Drill Bit Profile . All the PDC drill bit Desgin is basing on well and rock fromation condition .

All the design final destination is to improve the drill bit cutting performance.

4 . Drill Bit PDC Cutters

At the heart of a drill bit are polycrystalline diamond composite (PDC) cutters, which engage directly with the rock, using primarily shearing action for removal. In the demanding environment of a well, PDC cutters undergo frequent heating and cooling cycles, which pose significant challenges.

PDC cutters with improved thermal stability and reduced thermal degradation tend to perform better, resulting in higher rates of penetration (ROP) and improved wear resistance. Optimising these cutters is therefore critical to maximising effiency.

5. PDC Drill Bit Nozzles

PDC Drill bit nozzles help clear the cutting area and cool the Polycrystalline Diamond Composite (PDC) cutters.

Effective placement of these nozzles along with the angle they are set at plays a critical role on how efficient the drill bit performs.

Fluid channels also complement nozzle placement to improve the clearing of cuttings.

6. Steel Body PDC Bits

Steel body of PDC Bit is the opposite of matrix body. It can of withstanding high impact loads, but is softer and lacks protective features. The strength and ductility of steel give steel-bit bodies high impact resistance.

Steel bodies are considerably stronger than matrix bodies.

A beneficial feature of steel bits is that they can easily be rebuilt a number of times because worn or damaged cutters can be replaced rather easily. This is a particular advantage for operators in low-cost drilling environments.

Polycrystalline diamond compact (PDC) drill bits are different than roller cones in that they are one piece bodies with no moving parts. The fixed-cutters shred the rock, so the bit is able to operate with higher rotation speeds more efficiently in consolidated formations.

|